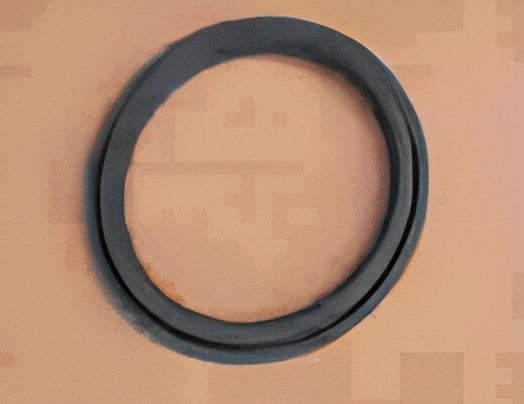

DOME SEAL NEOPRENE

DOME SEAL SILICON

CAST BASALT

CI BEND

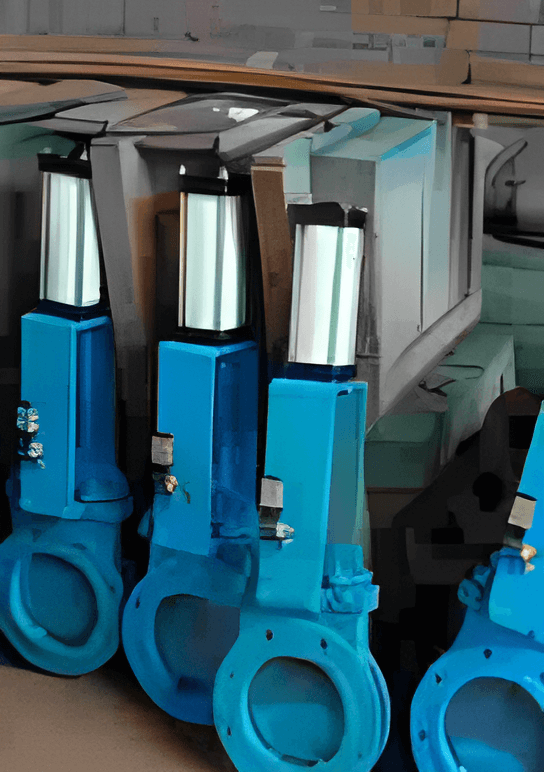

KNIFE GATE VALVE

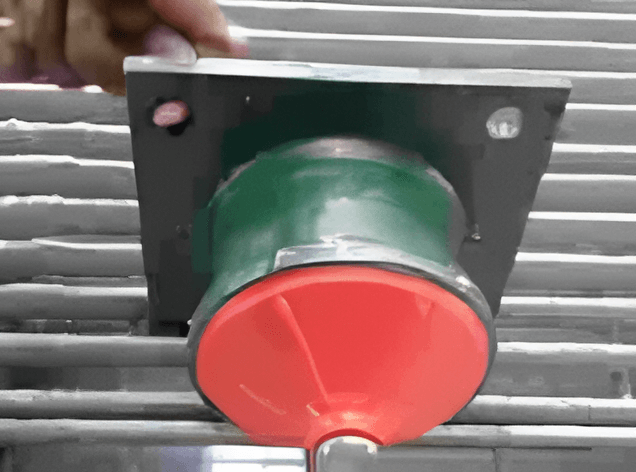

ASH INTAKE VALVE

DOUBLE DISK VALVE

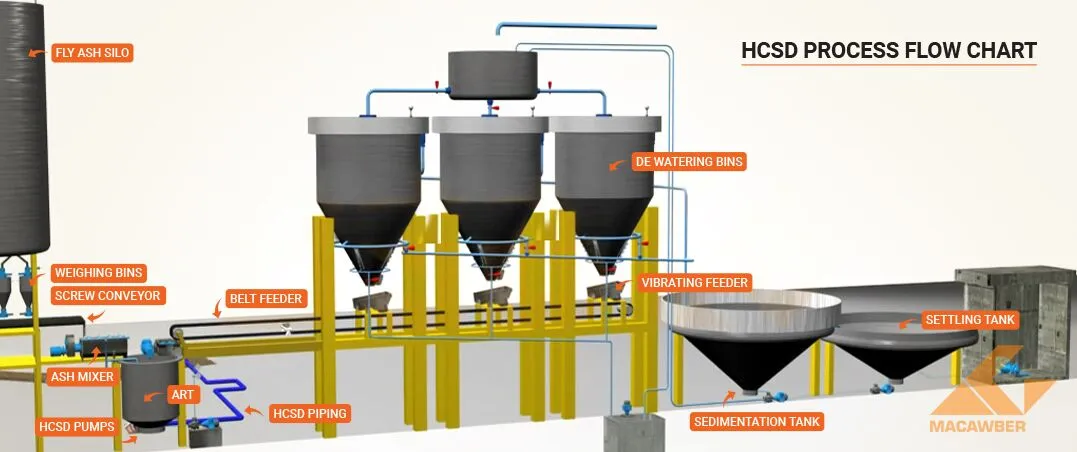

HYDRO EJECTOR

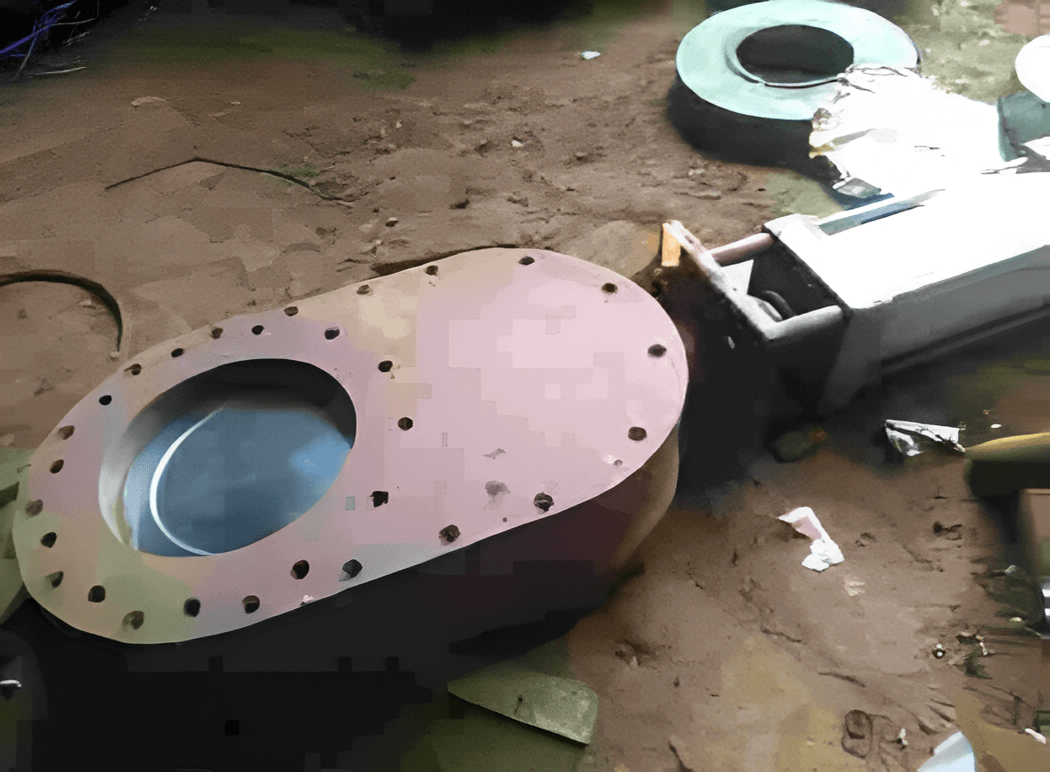

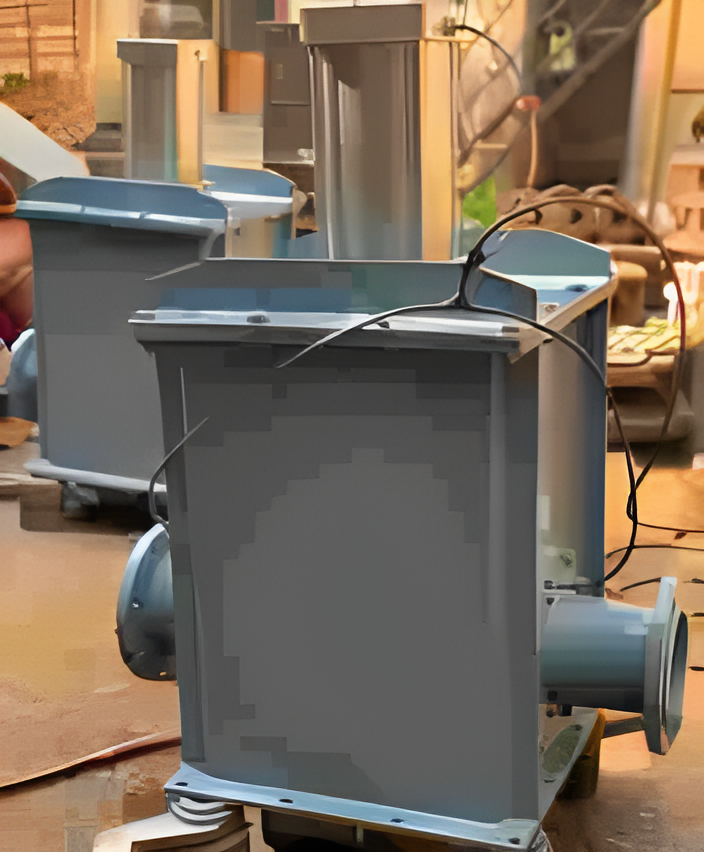

ASH VESSEL

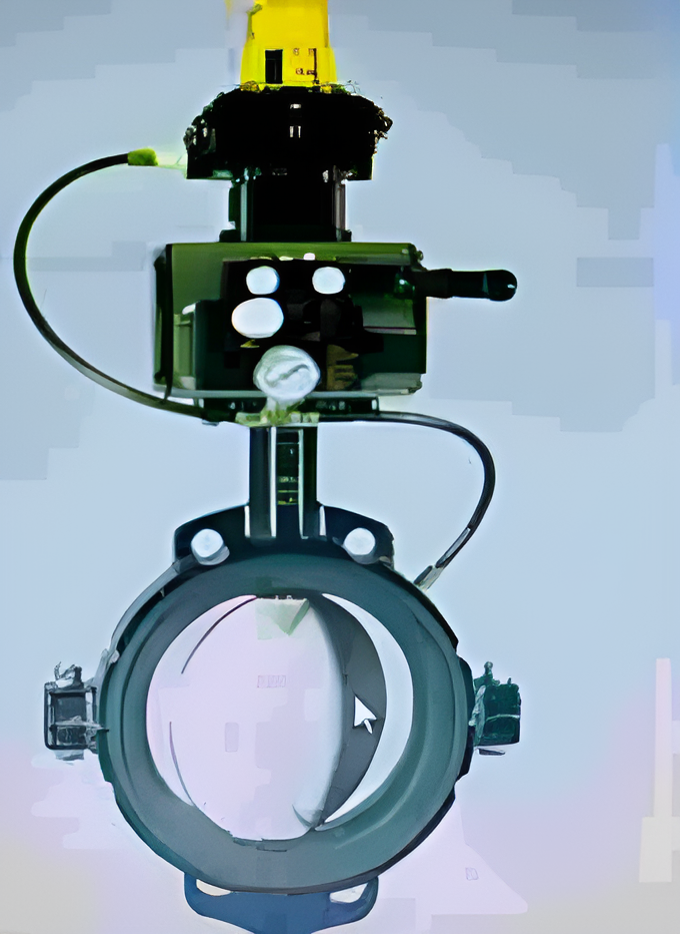

BUTTERFLY VALVE

FLOW CONTROL VALVE

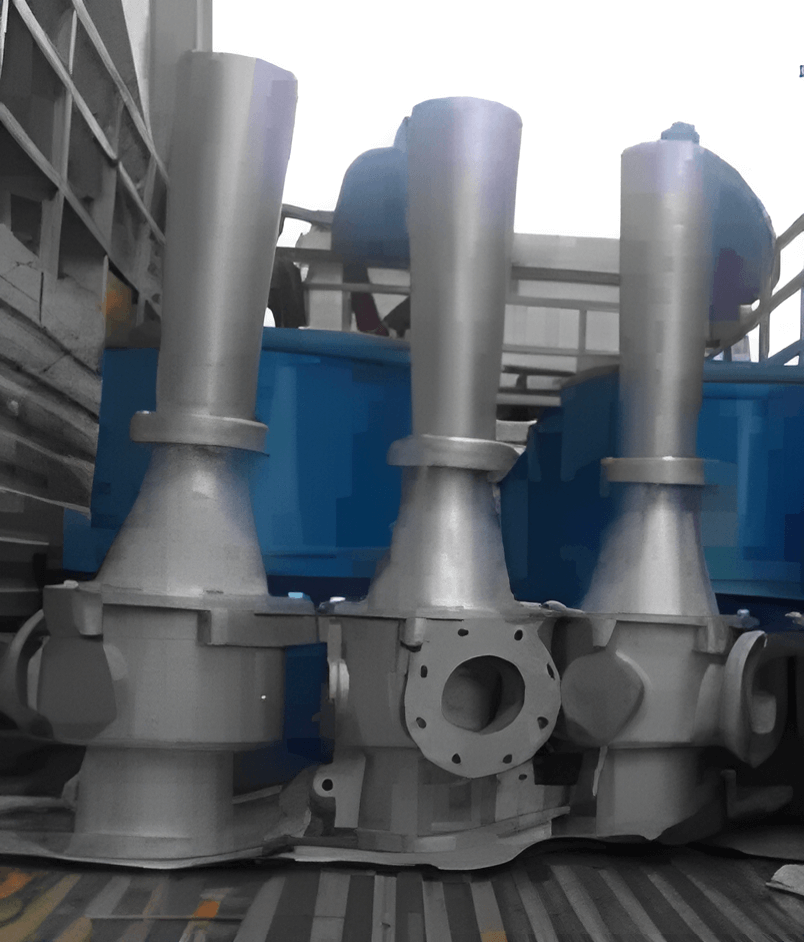

FEEDER EJECTOR

CERAMIC PADS & PIPE FITTING

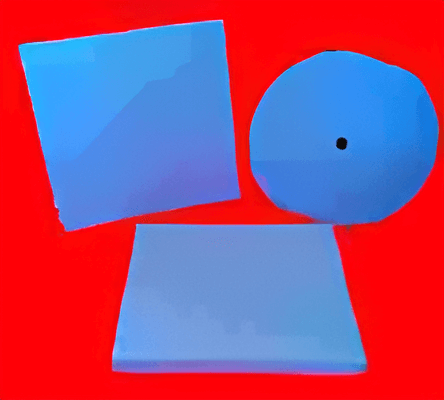

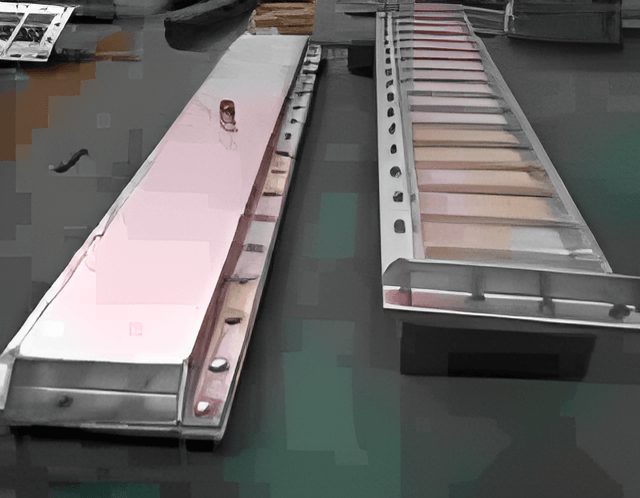

FLOW PADS

FLOW PADS

FLUIDIZING PADS

FLUIDIZING PADS

HYDRAULIC SYSTEM

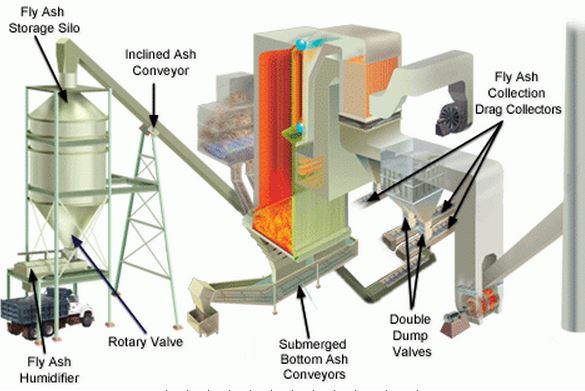

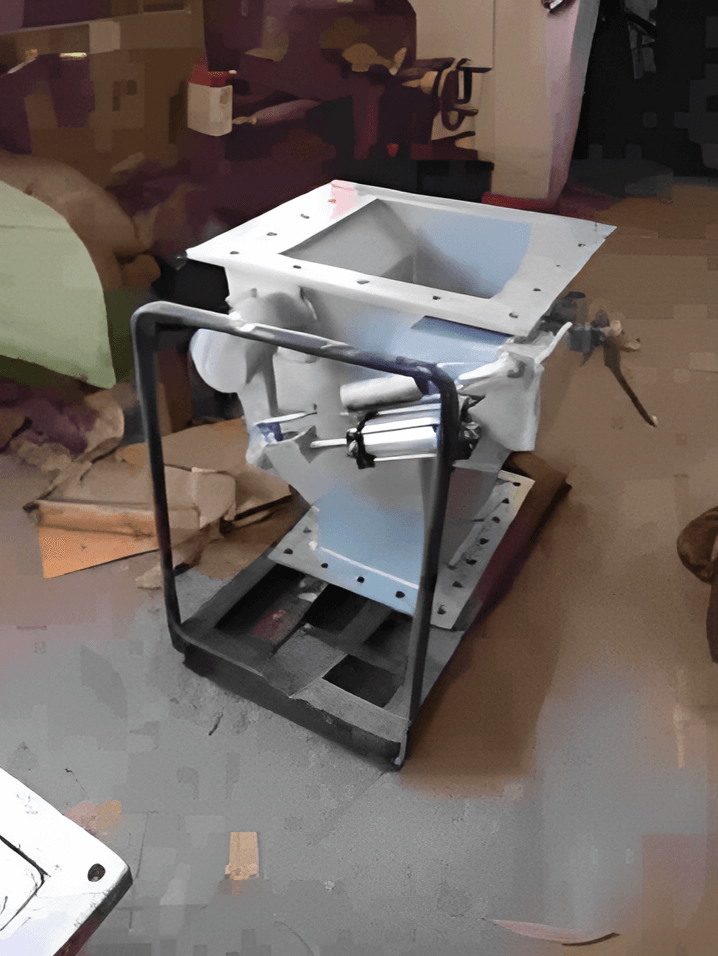

ROTARY FEEDER

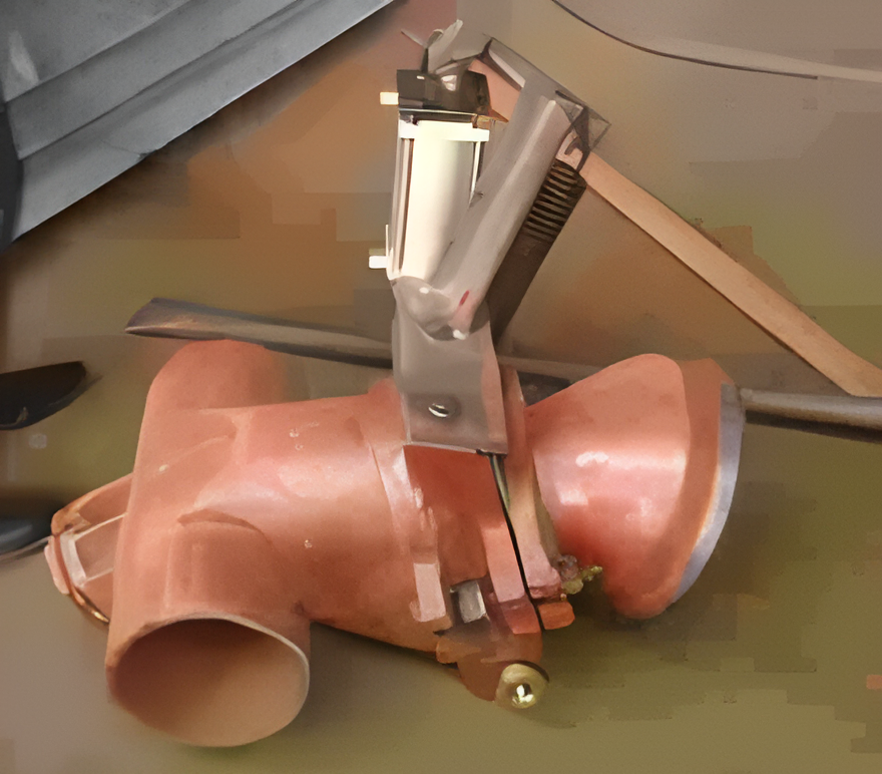

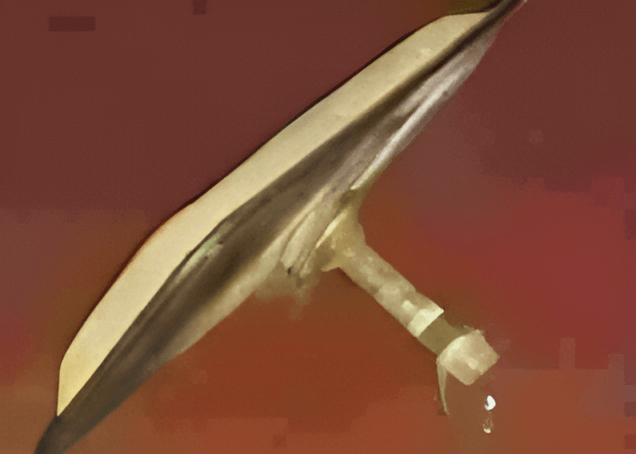

DOUBLE FLAP VALVE

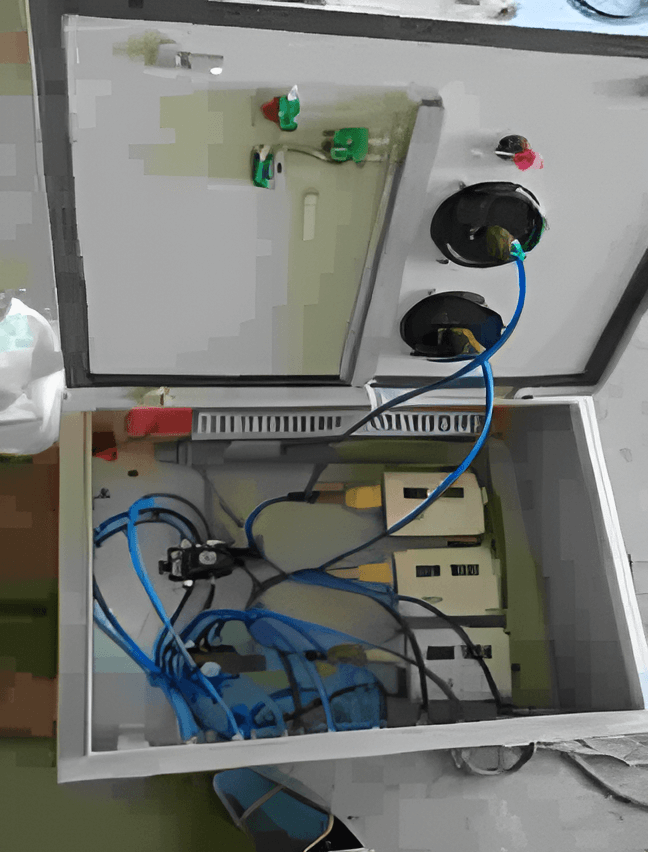

PLC CONTROL PANEL

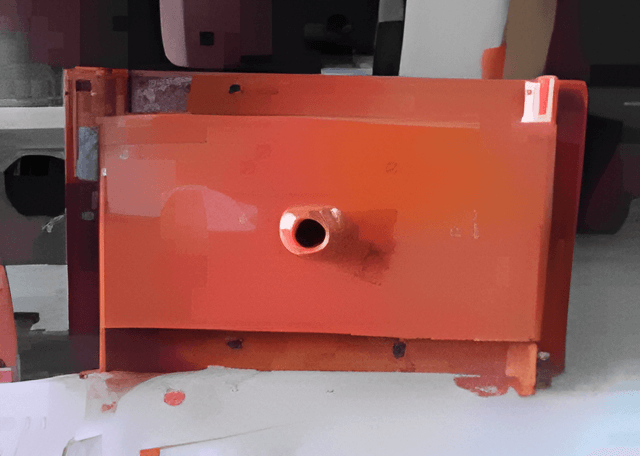

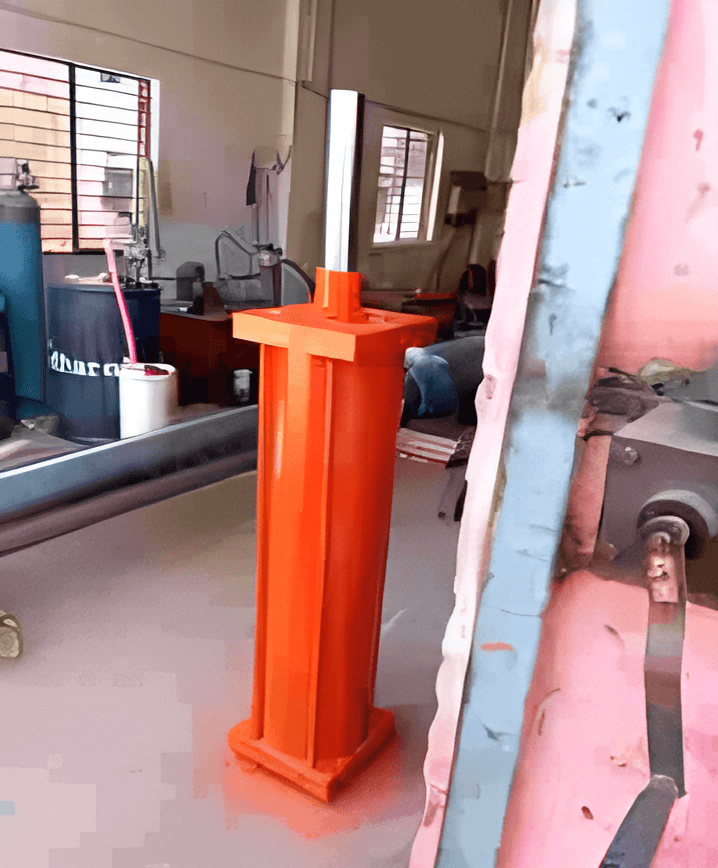

HYDRAULIC CYLINDER